MADISON – Using the power of prediction, University of Wisconsin–Madison mechanical engineers have quickly discovered several promising high-performance polymers out of a field of 8 million candidates.

The aerospace, automobile, and electronics industries use these polymers, known as polyimides, for a wide variety of applications because they have excellent mechanical and thermal properties — including strength, stiffness, and heat resistance.

Right now, there’s a limited number of existing polyimides because the process of designing them is costly and time-consuming.

However, with their data-driven design framework, the UW–Madison engineers leverage machine learning predictions and molecular dynamics simulations to dramatically speed up the discovery of new polyimides with even better properties.

The team detailed its approach in a paper published this month in the Chemical Engineering Journal.

“Our findings have broad implications for the field of materials science and will inspire further research in the development of advanced data-driven techniques for materials discovery,” says Ying Li, an associate professor of mechanical engineering at UW–Madison who led the research. “Our design strategy is much more efficient compared to the conventional trial-and-error process and can also be applied to the molecular design of other polymeric materials.”

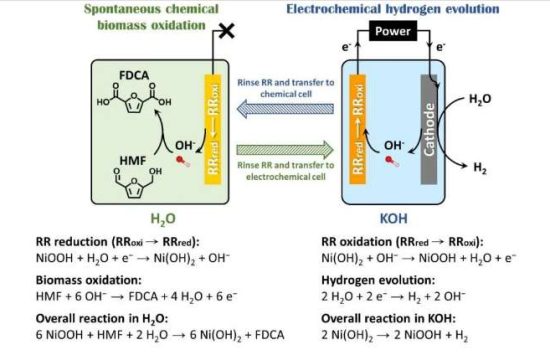

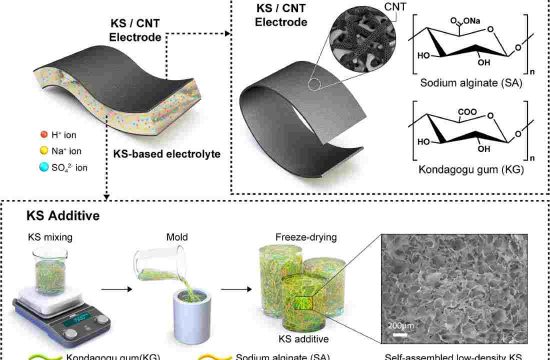

Polyimides are produced through a condensation reaction of dianhydride and diamine/diisocyanate molecules. For their study, the engineers first collected open-source data of the chemical structures of all the existing dianhydride and diamine/diisocyanate molecules, then used that data to build a comprehensive library of 8 million hypothetical polyimides.

“It’s kind of like building something with LEGO blocks,” Li says. “You have the basic building blocks — a whole bunch of different dianhydride and diamine/diisocyanate molecules. And you could try to build all of the possible structures by hand, but that would take forever because the various combinations are enormous.”

So, Li and his colleagues used a computer to combine the building blocks together, which allowed them to organize all possible combinations into a huge database.

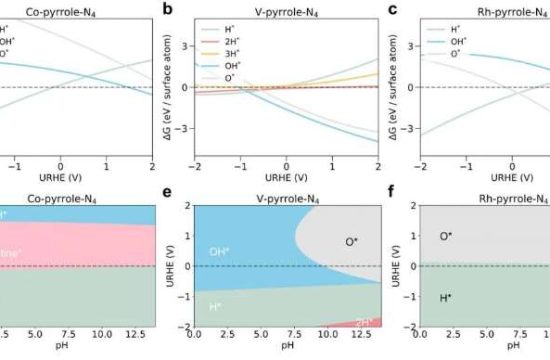

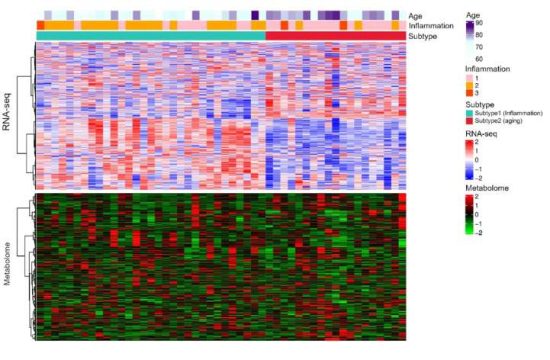

Database in hand, the team created multiple machine-learning models for the thermal and mechanical properties of polyimides based on experimentally reported values. Using a variety of machine learning techniques, the researchers identified chemical substructures that are most important for determining individual properties.

“We incorporated techniques that essentially explain how our machine learning model behaves, so our model isn’t a black box,” Li says. “We’ve built a transparent box that allows human experts to immediately understand why the machine learning model made a certain decision.”

Applying their well-trained machine learning models, the researchers obtained predictions for the properties of the 8 million hypothetical polyimides. Then they screened that whole dataset and identified the three best hypothetical polyimides with combined properties superior to those of existing polyimides.

They also checked their work: The researchers built all-atom models for their top-three candidates and conducted molecular dynamics simulations to calculate a key thermal property.

“The molecular dynamics simulations were in good agreement with the predictions from the machine learning models, so that gives us confidence that our predictions are quite reliable,” Li says. “In addition, the simulations showed that these new polyimides would be easy to synthesize.”

As a final validation method, the team made one of the new polyimides and performed experiments that demonstrated the material’s excellent heat resistance. Their experimental results showed the new polyimide could withstand a temperature of about 1,022 degrees Fahrenheit before it started to degrade — a result that agreed with their machine learning predictions. In contrast, existing polyimides could endure temperatures only in the range of 392 to 572 degrees F. The researchers also created a web-based application that allows users to explore the new high-performing polyimides with interactive visualization.

Additional authors on the Chemical Engineering Journal paper include equal-contributing first authors Jinlong He of UW–Madison, Lei Tao of the University of Connecticut, and Nuwayo Eric Munyaneza of Virginia Polytechnic Institute and State University. Vikas Varshney of the Air Force Research Laboratory, Wei Chen of Northwestern University, and Guoliang Liu of Virginia Polytechnic Institute and State University are also authors of the paper.

The research was supported by funding from the Air Force Office of Scientific Research through the Air Force’s Young Investigator Research Program, the Air Force Research Laboratory, and the National Science Foundation.