SUTD researchers refine two-photon polymerization lithography to create high-precision, nanoscale features, advancing 3D printing to enable the production of intricate components for use in high-tech applications.

From houses to hearing aids, three-dimensional (3D) printing is revolutionizing how we create complex structures at scale. Zooming down to the micro and nano levels, a process known as two-photon polymerization lithography (TPL) allows scientists and engineers to construct objects with microscopic precision, which has wide-reaching implications for industries ranging from medicine to manufacturing.

In computing and communication, for instance, TPL can be used to develop new optical materials, such as photonic crystals that can manipulate light in new ways. However, despite its promise, some challenges to fully harnessing its potential are still in the way. Chief among these is the challenge of achieving uniform shrinkage and feature sizes below the wavelength of visible light, which is essential when it comes to advanced light manipulation.

Addressing this challenge, a team of researchers led by Professor Joel Yang from the Singapore University of Technology and Design’s (SUTD) Engineering Product Development pillar —in collaboration with their counterparts from the Industrial Technology Center of Wakayama Prefecture in Japan—introduced a new method that ensures even shrinkage of 3D-printed structures when heat treated. This further refines the usage of TPL in producing high-precision, nanoscale features.

Their research paper, ‘Pick and place process for uniform shrinking of 3D printed micro- and nano-architected materials’, was published in Nature Communications.

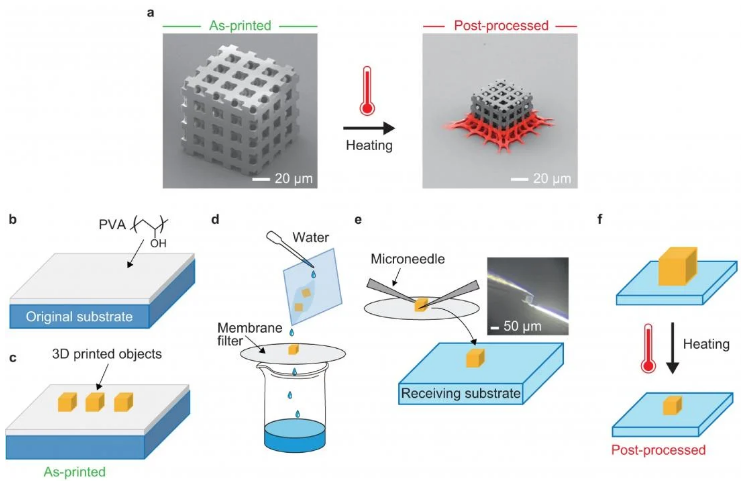

In their study, the researchers employed a layer of poly(vinyl alcohol), or PVA, on the printing substrate to facilitate 3D printed parts to be washed off and transferred onto a separate substrate thus enabling controlled and uniform reduction of 3D printed parts. The loose attachment onto the new substrate allowed the base of the structures to glide as the overall 3D print uniformly shrinks during heating. This simple yet effective approach circumvents the issue of non-uniform shrinkage caused by the attachment of the structure to the surface on which it was printed. It also opens up possibilities of transferring microscopic 3D printed parts for integration with other devices, or onto substrates that are not suitable for TPL.

Prof Yang drew inspiration from nature for this technique, stating, “Just as earthworms stretch and contract to move across surfaces, we believed we could enable our 3D structures to ‘glide’ to a smaller size without distortion.”

According to Tomohiro Mori, first author of the paper and visiting researcher from Industrial Technology Center of Wakayama Prefecture, “The complex geometry of the Wakayama prefecture’s mascot—with its various curves, bumps, and dips—made it an ideal subject to showcase our technique’s effectiveness. Successful uniform shrinkage of such a detailed model suggests that our method could be adapted for any form, irrespective of its shape or the solidity of the platform it’s placed on.”

The team’s approach enables the creation of finely detailed structures that surpass what their printing equipment can originally produce, breaking through previous barriers of resolution and material rigidity associated with 3D-printed objects.

By leveraging this new shrinking process, the researchers can also refine the features of 3D-printed structures to such an extent that they can function in new roles, such as visual indicators due to their ability to display structural colours. More importantly, these colours are not due to dyes but arise from the material’s internal structure, which, when reduced in size, interacts with light in a way that alters its appearance.

This introduces new functions to materials. “For example, incorporating certain molecules called chromophores, which are sensitive to different types of light, into the structures, could allow us to engineer materials that change colours in response to specific lighting conditions,” explained Prof Yang. “This has practical applications in anti-counterfeiting, where items can be verified as genuine through distinct structural colours and the emission properties of these materials.”

The technology developed by the research team holds promise in industries such as electronics, where it can be used to manufacture intricate heat sinks needed for cooling high-performance devices such as state-of-the-art GPUs and CPUs. The consistent shrinkage of printed components also opens up applications in fields that require high fidelity in material structuring, such as mechanical parts with complex geometries, optical elements with precise light-manipulation capabilities, and acoustic devices that can control sound with greater accuracy.

Looking ahead, the researchers plan to expand the applications of their technique beyond the current polymeric resin material used in their study. By applying their method to materials with higher refractive indices, they aim to create more effective photonic crystals, which could improve technologies in lasers, imaging systems, and optical sensors.

In addition, the research team is also working on fine-tuning the control of spacing in printed structures to produce full-colour, 3D models that can precisely control the way light is manipulated. This includes efforts to transfer and accurately position these structures over large areas or in significant quantities, maintaining the high precision required for these advanced applications.