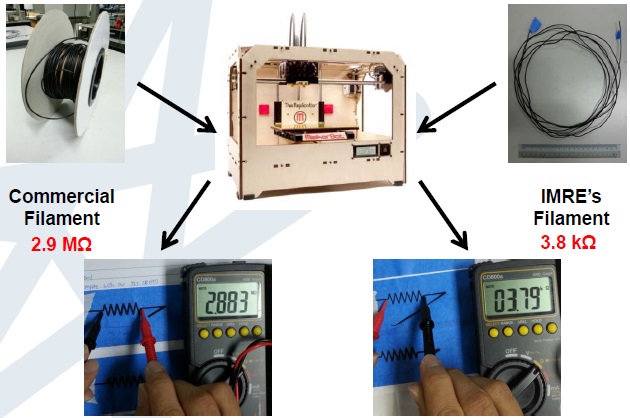

New material is 1,000 times more conductive than commercially available materials currently on the market.

Singapore—Scientists at A*STAR’s Institute of Materials Research and Engineering (IMRE) have invented a new type of thermoplastic thread that can be used in 3D printers to create functional circuits for use in electrical gadgets.

“I believe this will revolutionise desk-top manufacturing for electronic gadgets,” said Dr Johnson Goh, IMRE scientist and Head of the Science and Engineering Research Council’s (SERC) Nanofabrication and Characterisation Group and Principal Investigator of this project.

Dr Goh and his team have successfully used this new material to print prototypes such as a USB connector that can light up a LED bulb, complex three-dimensional circuits, and a wearable flexible sensor.

The resistivity of IMRE’s thermoplastic material is in the range of 0.5-1.0 Wcm, about 1,000 times more conductive than most commercially available plastic filaments for 3D printing. The filament is strong enough to stay intact throughout the 3D printing process in a conventional thermoplastic 3D printer.

“Objects in various colours, shapes and textures complete with functional circuits including wires, resistors and capacitors, could one day be printed in the comfort of one’s home,” said Dr Kwok Sen Wai, one of the key scientists in the team.

The team has found that using IMRE material to 3D print circuits rather than creating circuits through the conventional etching-and-soldering method is much safer, faster and cheaper. In addition, such circuits have highly uniform conductivity, with less than a 5 percent variation, compared to more than a hundred percent in commercially available conductive filaments.

“We believe that our material will encourage more innovation and entrepreneurship as it will empower people to make prototypes more easily and cheaply,” added Dr Kwok.

IMRE is actively looking for industry partners to commercialise the technology. The new technology is now available for licensing through A*STAR’s commercialisation arm, Exploit Technologies Pte Ltd (ETPL).