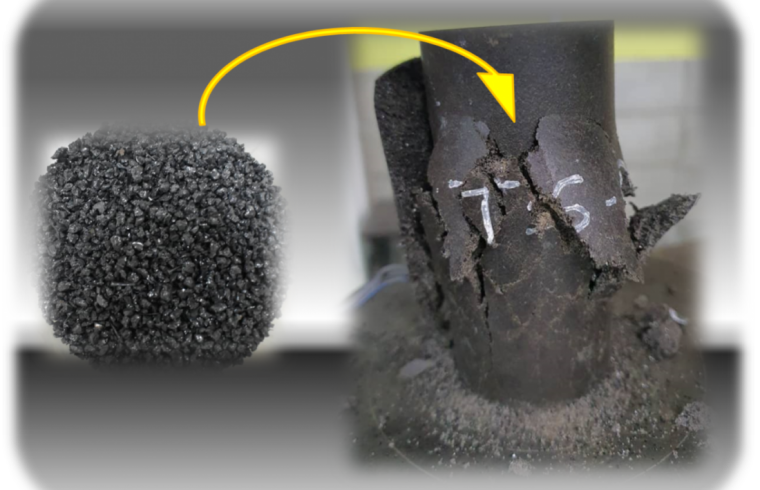

Scientists have reported a novel way to produce reinforced concrete materials using tin slag aggregates, which is a by-product of the smelting process. This way of producing concrete enables tin slag to become a useful material, as well as reducing the number of natural resources used, which in turn contributes to reducing the carbon footprint in the construction industry.

Concrete as we all know is used in the construction industry. Astonishingly, concrete is the second most widely used material in the world; the first is water. The production of conventional concrete is an energy-intensive process that involves lots of natural resource consumption. Thus, reducing the reliance on concrete or the amount of concrete is paramount to reducing the carbon footprint of the construction industry.

Associate Professor Dr Shukur Abu Hassan, Director of Centre for Advanced Composite Materials, Universiti Teknologi Malaysia (UTM)) has successfully developed a method that uses tin slag particles as a natural aggregate replacement and polymeric resins as an alternative to cement binders forming new composition of polymer concrete composites as a mean of reducing the use of conventional cement-based concrete.

Tin slag is a blend of tin and silica. Of noteworthiness is that tin slag is a by-product of the smelting process, and using tin slag for the construction industry has the advantage of ‘upcycling’ the tin slag by putting it to good use.

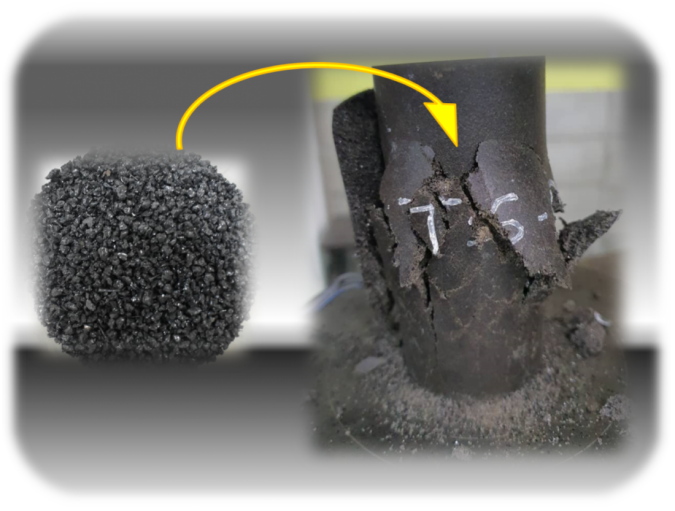

Prof. Abu Hassan and his team have been studying the use of tin slag particles as fillers for concrete. In recent times, their hard work has led to the development of a novel method of producing highly durable polymer concrete by incorporating tin slag particle aggregates.

Such as polymer concrete can be fabricated into structures, i.e., either for primary or secondary structural applications. Durability was demonstrated by studying the tin slag polymer concrete samples in indoor, outdoor (tropical climate) and industrial aggressive environments for 12 months.

The results revealed that tin slag polymer concrete samples reinforced with carbon fibre/epoxy (CFRP) or glass fibre/epoxy (GFRP) composites showed a significant enhancement in terms of strength and modulus compared to unconfined sample groups although the compressive strength and modulus deteriorated when exposed to tropical climate due to the moisture ingression tin slag polymer concrete.

The other team members are from UTM, namely Professor Mat Uzir Wahit, Dr Balqis Omar, Muhamad Faidzal Mohd Yusuff, Dr Umar Abdul Hanan, Khidzir Zakaria, Professor Mohd Yazid Yahya, Abdul Rahman Mohd Sam, Siti Safarah Amirnuddin, and from Universiti Malaysia Pahang, namely Assoc. Prof. Dr. Mohd Ruzaimi Mat Rejab, Dr. Januar Parlaungan Siregar and Muhamad Soffi Manda.

Recently, the study is heading in a new direction to develop better control of the interface between the tin slag and the polymer composite material by introducing compatibilizers. Consequently, the new direction embraced an expanded team that includes researchers with relevant industry 5.0 backgrounds, i.e. production and materials technology: Dr JS Binoj (Saveetha Institute of Medical and Technical Sciences) and Associate Professor Kheng Lim Goh (Newcastle University in Singapore).