An international team of researchers revisited the fundamentals of Negative Poisson’s ratio structure (NPRS) and investigated its creation using laminated carbon fiber reinforced plastics, a strong and lightweight material.

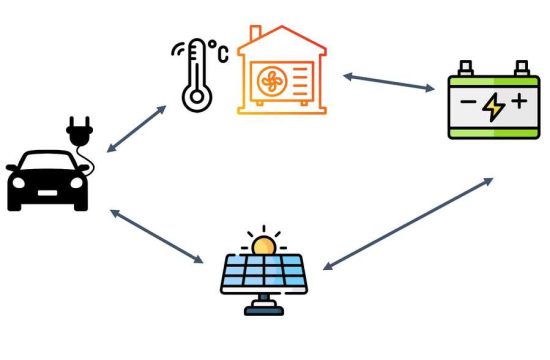

The objective was to gain a deeper understanding of the process and explore potential applications— researchers aiming to unlock new possibilities and advancements in the field of materials science for sustainability.

NPRS is a special kind of material that has been extensively studied for its ability to absorb impact energy effectively. It has the potential to be used for protecting lives during collisions, such as in a car accident on the road.

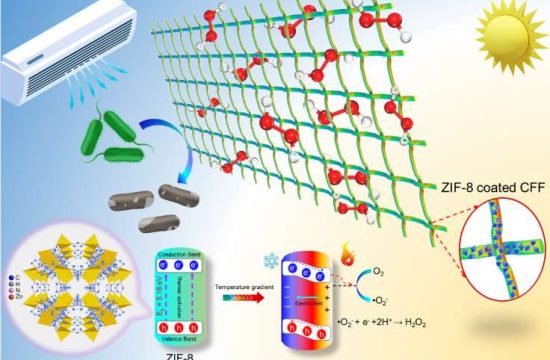

To tackle the challenge of making NPRS lightweight, e.g. for meeting electric vehicle’s energy efficiency, the researchers discussed the basic concepts of NPRS and how it can be made using a specific type of strong and lightweight material called laminated carbon fiber reinforced plastics (CFRP). They also used a method called finite element analysis (FEA) to study the mechanical behavior of the CFRP-NPRS.

Additionally, they explored the future applications and development of CFRP-NPRS for lightweight cushioning and energy absorption. The study found that the CFRP-NPRS may experience cracking, delamination, and shear fracture near the corners, and a closed structure may undergo deformation.

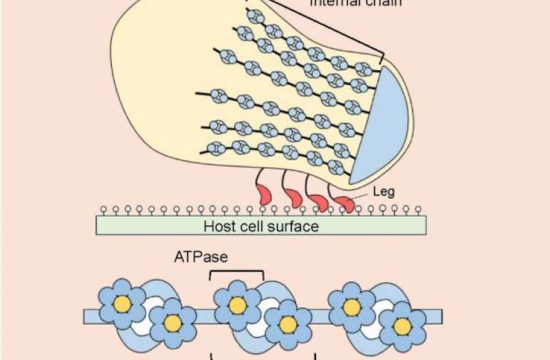

When the opening structure and closed structure are combined, the closed structure plays a more significant role in the deformation. The NPRS property of CFRP-NPRS is observed through the inward contraction of the cross-beam. The stress on the beams shows an alternating distribution pattern, and the layer of fibers called the 0-fiber layer mainly carries the load.

The study was led by Dr. Zhao Chang Fang, a young researcher who has recently completed his Ph.D. study at Nanjing University of Science and Technology in China, and who was a visiting scholar at Newcastle University Singapore and the National University of Singapore in the past.

The research has been published in Materialstoday on June 22, 2023.