Researchers have developed a practical way of studying the intralaminar crack propagation of unidirectional fiber-reinforced polymer composite (GFRP) laminate.

The novel approach was also implemented by finite element analysis (FEA) and validated by a tensile/compression experiment.

A lead researcher Changfang Zhao from Nanjing University of Science and Technology said that a new way can be used to complement the inspection of laminated structures that are used as primary structures in many industries.

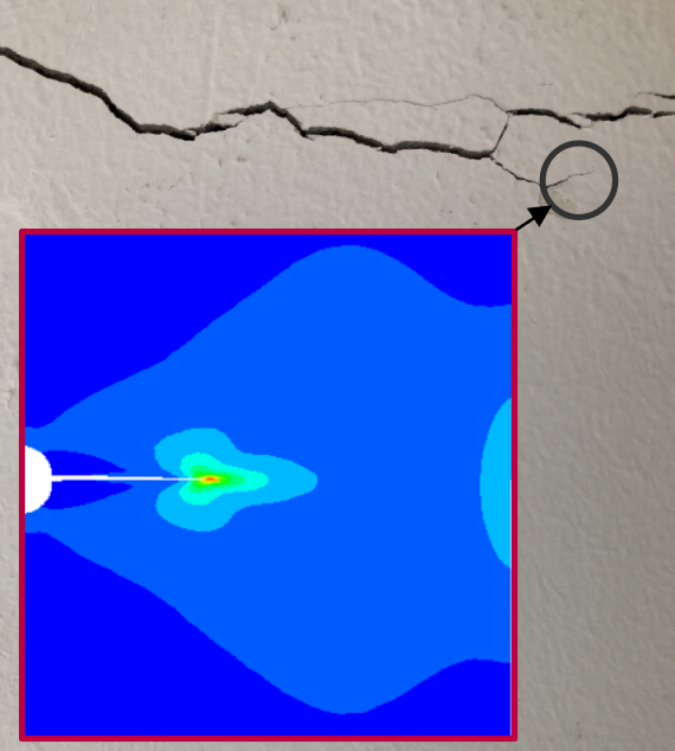

According to research the novel approach using FEA was conducted using a progressive damage model (PDM) -which was executed by using the implicit user material (UMAT), explicit user material (VUMAT), the extended finite element method (XFEM) subroutines completed by a microscale model of crack propagation that was implemented using a representative volume element (RVE) algorithm.

The results from the predictions agreed very well with experimental results from mechanical testing and scanning electron microscopy (SEM).

In addition, using a blended approach for FEA simulation, namely by combining the PDM and RVE with XFEM subroutines, could be a step forward in simulating the intralaminar crack propagation phenomenon in order to gain deeper insights into the micro-macro failure mechanism.