Condensation is critical for applications like power generation, water harvesting, and cooling systems. However, traditional surfaces suffer from a drop in performance under high subcooling, when the surface temperature is much lower than the surrounding vapor. This leads to water flooding and reduced heat transfer.

To tackle this long-standing challenge, researchers at National Taiwan University and National Chung Hsing University have developed a novel three-dimensional (3D) hybrid surface that significantly enhances condensation performance and avoids flooding, even at high subcooling.

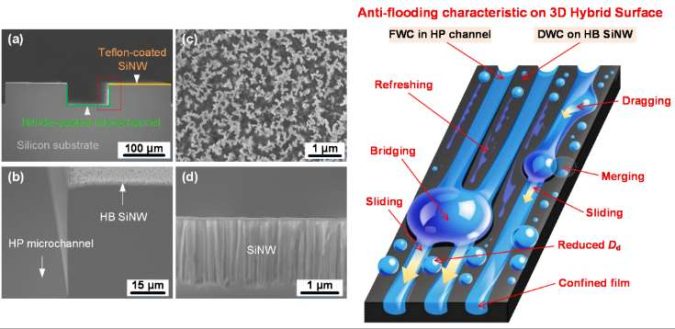

The new surface integrates short hydrophobic nanowires and hydrophilic microchannels in a structured pattern. This combination helps guide water droplets efficiently off the surface, preventing the accumulation of water that typically hampers heat transfer.

Unlike previous designs, this surface sustains both dropwise condensation for high heat transfer and controlled filmwise condensation in confined regions to guide drainage, enabling stable performance across a wide range of temperatures.

Experimental results demonstrated that the surface with the narrowest microchannels (named N100) achieved the best performance. It maintained a stable and high heat transfer coefficient of 38.3 kW/m²·K at a subcooling of 16 K—216% higher than a conventional hydrophilic surface.

On the N100 surface, large water droplets were removed efficiently through sliding motion along the microchannels, as the confined film helped reduce adhesion and promoted droplet departure.

This innovation offers a robust solution for improving condensation in practical applications like heat exchangers, air conditioners, and desalination units. Its stability and performance across temperature ranges represent a significant step forward in heat transfer materials.

“This research shows how smart surface engineering can overcome the limitations of current materials and improve energy efficiency in real-world systems,” said Prof. Ming-Chang Lu.